Switzerland was already familiar with independent vehicle manufacturing from brands such as Martini, Turicum and others. In Switzerland, premium brands were outfitted with premium bodywork. Foreign vehicles, however, were also fully assembled in Switzerland. For example, approximately 30 000 vehicles were built between 1949 and 1972 in Schinznach-Bad by AMAG and Automontage Schinznach AG respectively.

Schinznach-Bad, a small municipality in Aargau, received its current name in the 1930s and became one of the largest vehicle manufacturing centres in Switzerland shortly after the Second World War. But why Schinznach-Bad, a sleepy village in the Aaretal, of all places?

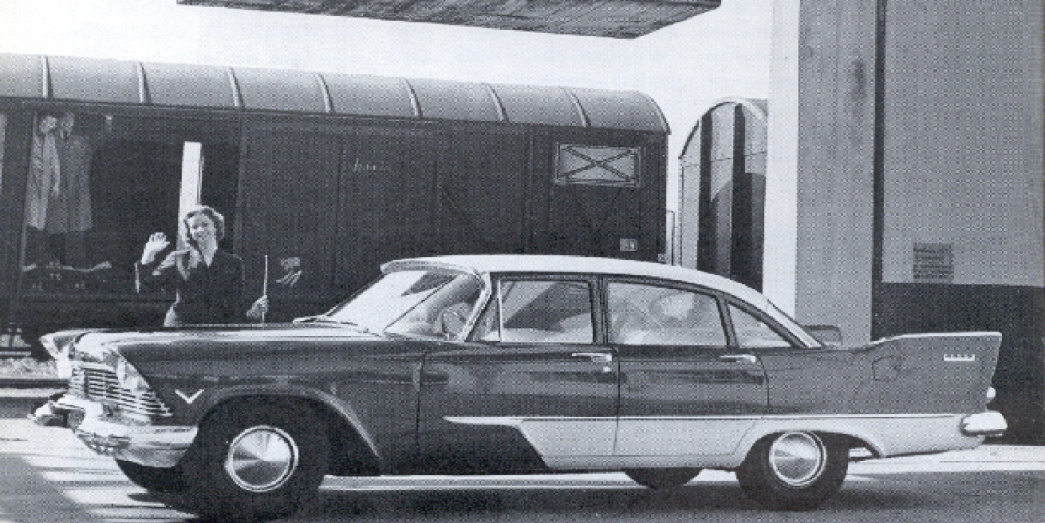

During 1949, Automontage Schinznach AG (ASAG) started assembling the first Plymouth and Standard sedans.

Even though in the public’s perception AMAG assembled vehicles in Schinznach-Bad, that is not entirely correct from a legal standpoint. Assembly operations were performed under a legally independent company, Automontage Schinznach AG (ASAG), which like AMAG, belonged to Walter Haefner Holding AG. The assembly company was not affiliated with the garage business located in Basel, which was also named ASAG.

Over the years, necessity became a virtue. What began in Schinznach as a result of financial concerns, very quickly developed into a premium label. The manufacturing quality of the body frameworks, anti-corrosion treatment and materials used, which were partially produced in Switzerland, were significantly better. And in the case of Switzerland, “Montage Suisse” vehicles were better outfitted than their American prototypes.

Willy Huter, the long-serving and sole director of vehicle assembly, summed it up well in the 1950s: “The ‘Montage Suisse’ label in fine print on all the vehicles we assemble must be a guarantee of the highest quality at all times!”

In 1945, employees were told: “From the very first work step, vehicle assembly technicians must realise that we mean business and that the quality of their work determines sales success, customer satisfaction and the security of their own livelihoods. A good man has a sense of pride and follows through on his own motto: ‘I never botch things!’ And as we all know, the ‘Suisse’ Plymouth is one of the greatest successes on the Swiss market.”

The first 10 years of assembly operations could be described as “The Plymouth Years”. Already in the first year of assembly, 66 vehicles rolled off the assembly line in Schinznach-Bad. Over 7100 vehicles had been built by 1959. In comparison, the production numbers of other carmakers – 42 Chrysler and around 250 DeSoto and 250 Dodge vehicles – look very modest. At the beginning of the 1950s, the delivery reliability from Detroit was very bad. People in Schinznach-Bad were thus glad that more than 500 Standard Vanguards could be built to bridge the gap and ensure capacity utilisation.

As American vehicles became larger and larger at the end of the 1950s – “The American automobile business has entered a new era. The cars are longer, wider and more expensive, and customers first need to get used to them ... These attractive and fast cars don’t sell themselves automatically. The tendency of today’s prospective customers to sacrifice the comfort they desire to buy a vehicle that is smaller than the large current American models needs to be overcome.” – people in Schinznach-Bad were grateful that around 1000 units of the then new, sleek Karmann Ghia coupé could be assembled in Switzerland – to relieve the burden on production in Osnabrück.

While the American vehicles were delivered completely as individual parts, Karmann delivered complete body frameworks that had to be equipped with doors and bonnets in Switzerland. After corrosion protection was applied and the paintwork was finished, “only” the final assembly was performed in Switzerland.

The short-term production of Studebaker vehicles starting in 1959 can be described as an interlude. The bankruptcy of the American company prevented it from enjoying greater success.

The Swiss no longer found the large American vehicles so practical. European alternatives were more compact and proved more practical, and the VW Beetle, also imported by AMAG, had long since begun its victorious campaign on Swiss roads. Alternatives were in high demand. The solutions were the 1960 and 1961 Chrysler Valiant and Dodge Dart. By US standards, the two models were considered compact mid-size sedans powered by in-line six-cylinder engines. AMAG even marketed the Valiant as an independent brand to clearly show that it was not a huge American land yacht.

Around 14 000 Valiants had been built by the time assembly operations in Schinznach-Bad were suspended. Sometimes it was a Chrysler, sometimes a Plymouth. The Dodge Dart, a sister model to the Valiant in terms of design, including the Dart HT and Demon subvariants, accounted for around 4700 units.

By the end of the 1960s, the American automotive industry was once again lapsing back into the realm of larger-than-life models, this time in terms of engine capacity and power. Unfortunately, the chassis and brakes of these vehicles did not do justice to the sheer power of the engines. In particular, the Swiss topography was not made for American muscle cars. This diminished interest in the Valiants and Darts. At the same time, thanks to Audi NSU Auto Union AG, which Volkswagen had acquired, AMAG suddenly had a new, more fuel-efficient range in the medium and upper-medium classes with the Audi 90, Audi 100 and NSU RO 80.

The demand for vehicles assembled in Switzerland experienced a steady decline. Vehicles could no longer be assembled at profitable margins. While assembly operations in Schinznach-Bad had commenced with a Plymouth, they were also drawn to a close in 1972 with a Plymouth, a Plymouth Valiant, after 29 227 units. The import contract for vehicles from the Chrysler group continued until 1980.

The assembly plants at the Schinznach-Bad site were decommissioned. After a number of modifications, the assembly halls now house a large repair shop with a body shop, paint shop and spare parts warehouse as well as offices for AMAG Import Ltd. Schinznach-Bad still serves as the AMAG Group’s import centre after almost 60 years.

Not all cars assembled in Schinznach-Bad

‘Not every Chrysler Corporation vehicle sold by the AMAG Group was a genuine ‘Schinznach assembly’ car, in other words, a car assembled in Schinznach-Bad – even if it has an ‘Automontage Schinznach AG’ badge in the engine compartment. In the Valiant model series, for instance, only the four-door saloons were assembled in significant quantities in Schinznach-Bad. Other versions, such as the two-door and the estate version, were imported into Switzerland as complete vehicles. These vehicles were only checked in Switzerland and refinished, where necessary, for a ‘Swiss finish’. With the entire American import business in the hands of Automontage Schinznach AG, a corresponding badge was applied to the engine compartment of these vehicles, but no other externally visible assembly markings.

In the case of the more recent Valiant and Dart models, in particular, the vehicle identification number indicates whether the car is ‘truly Swiss’. If the seventh digit of this number is 8, the car was also assembled in Switzerland.’

The advantages of Swiss assembly from the perspective of a copywriter in 1956:

PLYMOUTH SUISSE: even more beautiful, even more exclusive!

It would most certainly be understandable if you chose your new PLYMOUTH SUISSE exclusively for its technical sophistication and paid no particular attention to the sheer superiority of its body style and equipment. But it is precisely the traditional craftsmanship of SWISS ASSEMBLY that lends it an extra powerful impetus. Now more than ever, the impeccably tuned and remarkably complete equipment of the 1956 PLYMOUTH SUISSE enhances its superior performance and explosive power. Marvel at the weightless line of the new model, which is not cluttered by any ornamentation that is not intrinsic to its essence. People will look at you with deep admiration when you sit behind the wheel of this dream car that has turned into reality.

You are free to choose from innumerable modern yet timeless colours and combinations. The fabric and imitation leather upholstery of the seats – woven specifically for the PLYMOUTH SUISSE – underline its exquisite design. The PLYMOUTH SUISSE – without denying its status as one of the most affordable American cars – has moved into the class of true luxury vehicles. Is it any wonder that the 1956 PLYMOUTH SUISSE was hailed – and purchased – by countless motorists as the most beautiful of its kind?